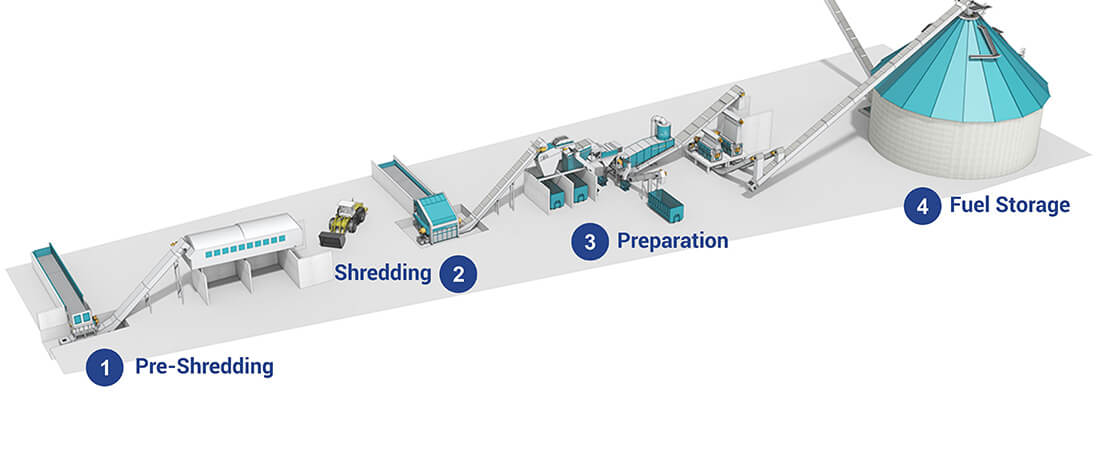

Waste to Flame

Waste to Flame solution is designed especially to meet the needs of Cement Kilns for recovered fuels production and handling.

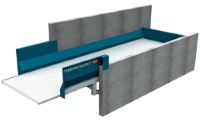

TYRANNOSAURUS® Feeders

TYRANNOSAURUS® Feeders enable optimal feeding to the shredder/crusher ensuring continuous maximum capacity.

TYRANNOSAURUS® 1500 Fines Screens

TYRANNOSAURUS® Fines Screen separates fines, for example, sand, glass, soil from the material.

TYRANNOSAURUS® 6600 Pre-shredder

Are ideal for preparation of challenging waste to increase the capacity of the entire process or as a main shredder for grate firedboiler

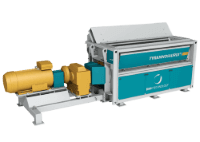

TYRANNOSAURUS® 1200 Fine Shredders

TYRANNOSAURUS® Fine Shredders are used to ensure the combustibility of the fuel by reducing the particle size as small as 25 mm.

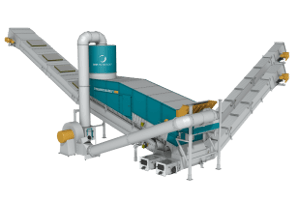

TYRANNOSAURUS® 2500 Air Classifiers

TYRANNOSAURUS®2500 Air Classifiers produce light and clean fraction to maximize the fuel quality

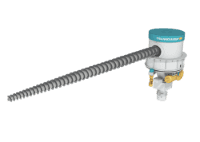

TYRANNOSAURUS® Rotating Screw Reclaimers

TYRANNOSAURUS® Rotating Screw Reclaimers are suitable to discharge solid fuels from silos or round open-air storages.

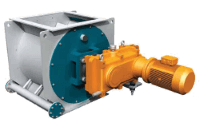

Rotary Valve Feeders

Rotary Valve Feeders are optimal solution for feeding and dosing variety of different fine-grained or dusty materialsThe turn-key solution includes the complete process from receiving waste to feeding it to the kiln. In Waste to Flame solution BMH Technology’s knowledge of fuel handling and technology of waste processing are combined together as efficient and reliable process solution.